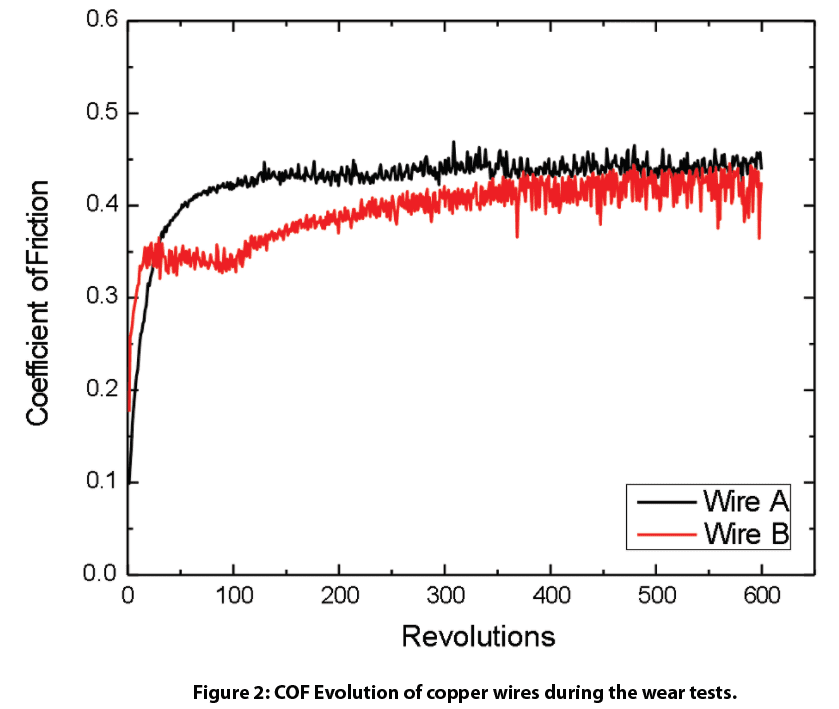

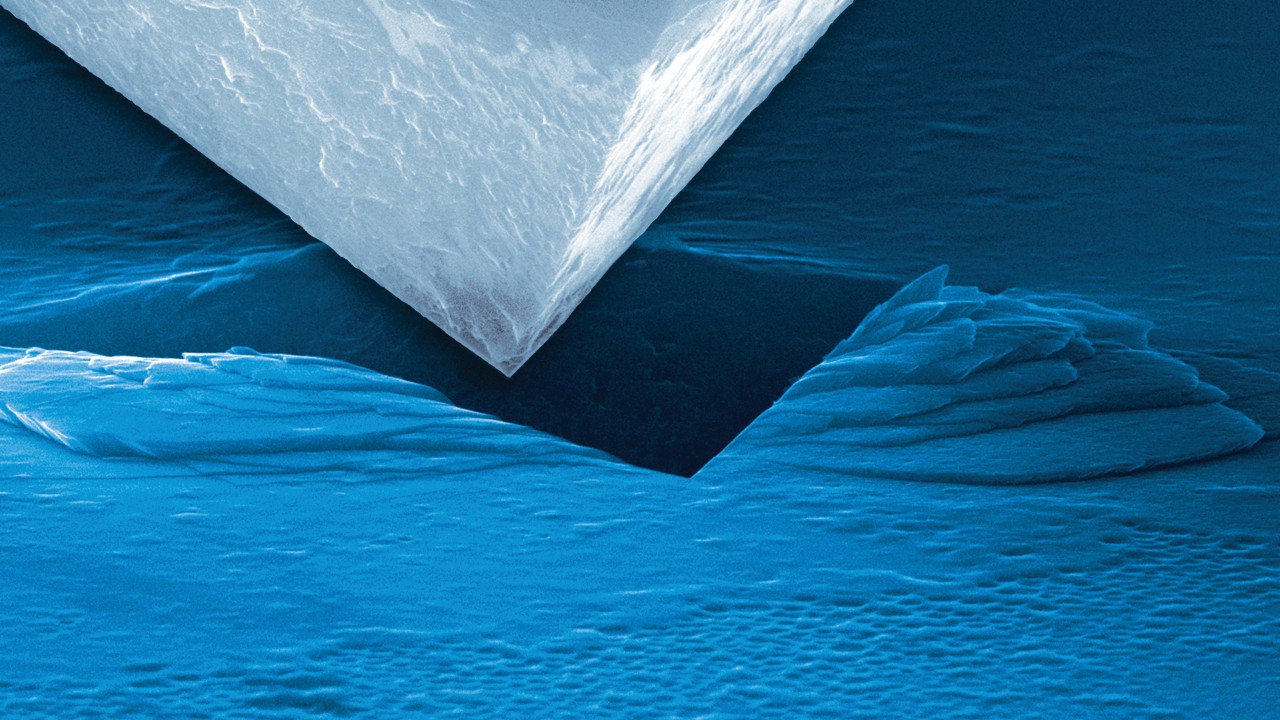

We simulate a controlled wear process of different copper wire surface treatments. Scratch testing measures the load required to cause failure on the treated surface layer.

Ultimate Guide - Stainless Steel - Fabrication, Grinding, and Finishing with Abrasives - Empire Abrasives

Surface morphologies of copper with different roughness values before

Anti-reflective, scratch-resistant coating for glasses and plastics - Innovation Hub@HK

🔥 【Nail tech must haves set for nail art】: You will get 1*15ml Base Coat+ 1*15ml Top Coat. It is normal for a base coat and color gel to remain a

modelones Gel Top Coat, 15ml No Wipe Clear Glossy Gel Base and Top Coat Set, Soak Off Nail Lamp Acid Free Base Top Gel Nail Polish Starter Kit

Nanomechanical Instruments for SEM/TEM

ProtectaClear 4 Oz. Clear, Protective Coating for High-Touch Metal

BUILDPRO MAX Slotted 4' x 3' Welding Table w/FREE Fixturing Kit

Wear and Scratch Evaluation of Surface Treated Copper Wire -NANOVEA

Schematic representation of the scratch channel obtained during scratch

High quality material: wire brushes set is made of stainless steel, durable, long service life on the toughest cleaning jobs. Practical tools: these

Rocaris Wire Buffing Wheel Brush Set, Wire Brush Set 1/8 Shank for Rotary Tools Accessories Polish Clean Tools, 120 Pack